Dreamworld Taipan Theme Park Entrance Canopy Description

The Steel Taipan ride at Dreamworld on the Gold Coast is the theme parks newest attraction. The AUD$32million roller coaster features a 1.2km track roller coaster and the Southern Hemisphere’s first triple launch system that launches the train forward, backwards, and then forwards again at a top speed of 105km/hr!

Fabritecture was contracted for the design & construction of a bespoke walkway canopy structure to shelter patrons as they wait in line for the Steel Taipan ride. The structure features custom printed Serge Ferrari PVC designed to match the architectural intent of the structure – to emulate the scales of a taipan snake!

Entrant: Atkins Fabrication (Aust) Pty Ltd - Fabricator

Location: Abilene - Texas USA

Client: USA Shade & Fabric Structures Inc.

Fabricator: Atkins Fabrication (Australia) Pty Ltd

This project was entered in the LSAA 2009 Design Awards - Medium Structures (#2129)

No further details have been entered at this stage.

APPLICATION OF PROJECT:

3 Pod like classrooms at Green School NZ

PROJECT DESCRIPTION:

To provide an outer skin from a material that can be recycled if/when replaced and also blends into environment. Wastage of non-recyclable materials to be kept to a minimum.

Also to provide the support frame to take the PVC membrane.

DESIGN / FABRICATION / INSTALLATION BRIEF

It was requested by the architect that we would supply a membrane solution for three-pod like classrooms for Green School New Zealand, to function as an aesthetic cladding and to create a ventilated thermal barrier to reduce a “heat soak effect” into the building. This was to complement the “green” label for the structure, reducing running costs and adding an organic look.

STRUCTURAL SYSTEMS

The overall complexity of the project was caused by the intriguing shape and challenging geometry, also the construction materials which were proposed.

The glulam timber beams implicated large tolerances on site, which required the steel components to be customized to match each of the three structures.

3d- digitizing of the design assisted by the construction of the tension-membranes. The high stretch of the fabric paired with the shape of the structures added the additional complexity of staged tensioning over multiple weeks.

MATERIALS

Mehler – Valmex Lodge de lux FR – 580gsm PVC

FABRICATION

The fabrication had complex geometry as the fabric had a high weft compensation which meant minimum tolerance to allow for the correct fit. The geometry for the fabric started with digital site measure using a Proliner first, followed by computer controlled cutting many checks and keder length dimensions to ensure accurate final panel size.

A similar process was used for the steel fabrication given the challenging geometry.

COLLABORATION, CONSTRUCTION AND MAINTENANCE

Being a bespoke membrane structure Cleland Construction Limited had to overcome the different approach from standard construction methodology and Fabric Structures & Cleland Construction work well to get the desired effect. This was mainly around a realization that fabrication off a 3D model was not going to create a successful outcome, therefore a proliner measure once the steel had been installed, then fabrication (with multiple QA check s) was agreed.

COSTS

Design – 12% Fabric – 6% Fabrication – 6% Steel – 50% Extrusion etc – 4% Installation – 22%

PROJECT CREDITS

Project Name Green School New Zealand

Location 406 Koru Road, Koru

City New Plymouth

Country New Zealand, 4374

Completion Date Oct-20

Category 2 Medium structures – 250m2 – 1000m2

Entrant Name Fabric Structures Limited

Address: 141 Dent Street,

Suburb: Central Business, Whangarei

Country: New Zealand, 0110

Telephone Land line: +64 9 4388343

Mobile: +64 275276452

Email Address:

Website address: www.fabricstructure.co.nz

Entrant Type / Role Designer / Fabricator / Installer

Project Client: Green School

Project Architect: Glen Brebner, Milca Severo, Boon

Structural Engineer: Fabspan/XiangDu

Specialist Consultant & Role: Kayne Jacobson, Project Manager

Building Contractor: Cleland Construction Limited

Fabricator(s): Fabric Structures Ltd – for membrane fabric

Others: Meco Engineering Co for Steel (under FSL contract)

Entrant: Taiyo Membrane Corp

Client: Taiyo Birdair Asia PTE LTD

Architect: Taiyo Membrane Corp

Structural Engineer: Robert McDonald (TMC)

Fabricator(s): Taiyo Membrane Corp

This project was entered in the LSAA 2007 Design Awards (Cat 2, 2002) Medium Fabric Structures

Application:

The project was designed to enhance the area around the mosque where believers come to pray. It allowed for a unique and innovative design for the Mosque and its congregation. Installed in Taman Rasuna, Jakarta, this outdoor area has been enhanced through the structures without it defaming the mosque and its ambient presence.

APPLICATION OF PROJECT

APPLICATION OF PROJECT

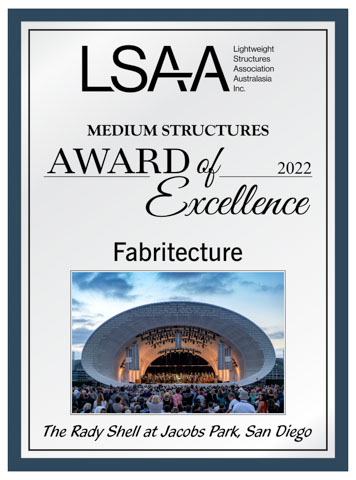

Outdoor concert theatre at Jacobs Park

The Rady Shell Concert Venue Description

The Rady Shell in San Diego Symphony’s new bay side venue is the first permanent year-round bay side concert venue in the nation operated by the Symphony Orchestra. The Rady Shell can accommodate audiences of 3,500 – 8,000 per concert and up to 10,000 for special events.

Fabritecture was engaged for the technical design and fabrication of the Rady Shell performance structure and surrounding pavilion structures. The Shell itself comprises a rolled steel frame and PTFE cladding. The entire structure is approximately 236,000lbs (107,000kgs or 107 tonnes).

The stage accommodates an orchestra size of up to 150 musicians and choir with a front of stage width of 32m and depth of 20m. The roof cantilevers 15m from the front of the stage and can carry a payload of up to 50T. The stage incorporates state of the art constellation sound system designed and engineered by Meyer Sound. This system provides an exemplary sound environment on stage for the musicians, whilst also providing the technical flexibility required for a variety of other performances

The overall project includes development of a range of public facilities, including restrooms, fitness facilities & rest areas. Food pavilions and a small stage are also part of the master design plan.

M6 Community Recreational Facility Description

As part of Transport NSWs upgrade to the M6 freeway Stage 1 development, new recreational facilities were developed to provide shade to the community in various areas including McCarthy and Brighton Reserve. As part of the McCarthy Reserve upgrade, Fabritecture was contracted for the design and construction of eight (8) structures to provide shade cover for recreational facilities over a playground. The structures feature both Gale Pacific 95 Mesh and architecturally perforated aluminium.

DESIGN / FABRICATION / INSTALLATION BRIEF

Transport for NSW is delivering new recreational facilities for the Bayside Community before construction begins on Stage 1 of the M6 motorway in Rockdale, NSW. Fabritecture was contracted for 8 structures for installation at McCarthy Reserve. The structures are a combination of mesh shade structures clad with Gale Pacific Commercial 95 Heavy shade cloth, and aluminum architectural metal structures with custom artwork perforations in the panels.

STRUCTURAL SYSTEMS

The aluminium structures feature a steel frame with a grid system for the aluminium. The perforated panels are underslung, so the custom perforated artwork can be seen clearly from underneath the structures in the playground.

The shade structures are also steel framed and are tensioned using a Fabritecture extrusion system.

MATERIALS

The chosen material for the shade structures was Gale Pacific Commercial 95 340 Mesh, in 4 colours: Aquatic Blue, Desert Sand, Yellow and Orange. The fabric was chosen based on the colour specifications from the client.

The aluminium panels for the architectural metal structures was 6mm thick with a Colourbond Monument equivalent RAL 7021 with custom artwork perforations.

FABRICATION

The aluminium artwork features custom perforations in the patterning of native flora such as bottlebrush, and flora such as birds and frogs. There are 6 mesh structures in total at McCarthy Reserve, with 4 having an 8m diameter, and 2 with an 11m diameter. The 2 aluminium structures are 11m and 17m in diameter.

COLLABORATION, CONSTRUCTION AND MAINTENANCE

The installation of the structures occurred over existing playground equipment. This required specific planning. Construction involved the installation of all columns first and preassembling of roof discs on the ground. These were then crane lifted into their final install position. There was no overhead install.

Gale Pacific Commercial 95 340 Mesh is used widely for projects that require maximum sun protection and strength. The durable mesh fabric has low maintenance requirements and a long life performance.

COSTS

The M6 Community Recreational Facility project was valued at approximately AUD$730k.

PROJECT CREDITS

Project Name: M6 Community Recreational Facility

Location: West Botany Street

City: Rockdale, NSW, 2216

GPS Location: -33.955663, 151.146580

Completion Date: 12-Oct-21

Category (1-8): 2 – Medium structures

Entrant Name: Fabritecture

Address: Unit 14/15 John Duncan Court, Varsity Lakes, QLD 4227

Telephone: +61 7 5587 7000

Mobile: +61 408 402 716

Email Address:

Website Address: www.fabritecture.com

Entrant Type / Role: Designer / Fabricator / Installer

Project Client: Transport NSW

Project Architect: Design Inc.

Structural Engineer: Greenup Design Engineers; Cardno

Building Contractor: Ertech Pty Ltd

Fabricator(S): Confidential

Project entered into the LSAA 2016 Design Awards (Medium Fabric Structures Entry 2698)

Entrant: Structureflex (Designer / Engineer)

Location: Echuca, Victoria. Completed: January 2015

Client: St Joseph's Catholic College

Team: Y2 Architects, Steve Huppert, John Killmister (Cert. Eng), Shade Living Pty Ltd, Fabric Solutions (membrane), Thornton Engineering (steel)

Application

As part of a new gymnasium and music centre it was proposed to extend a covered outdoor area over the new netball court that adjoins the building with a 38m x 22m PVC barrel arch roof structure attached to new steel framed gymnasium.

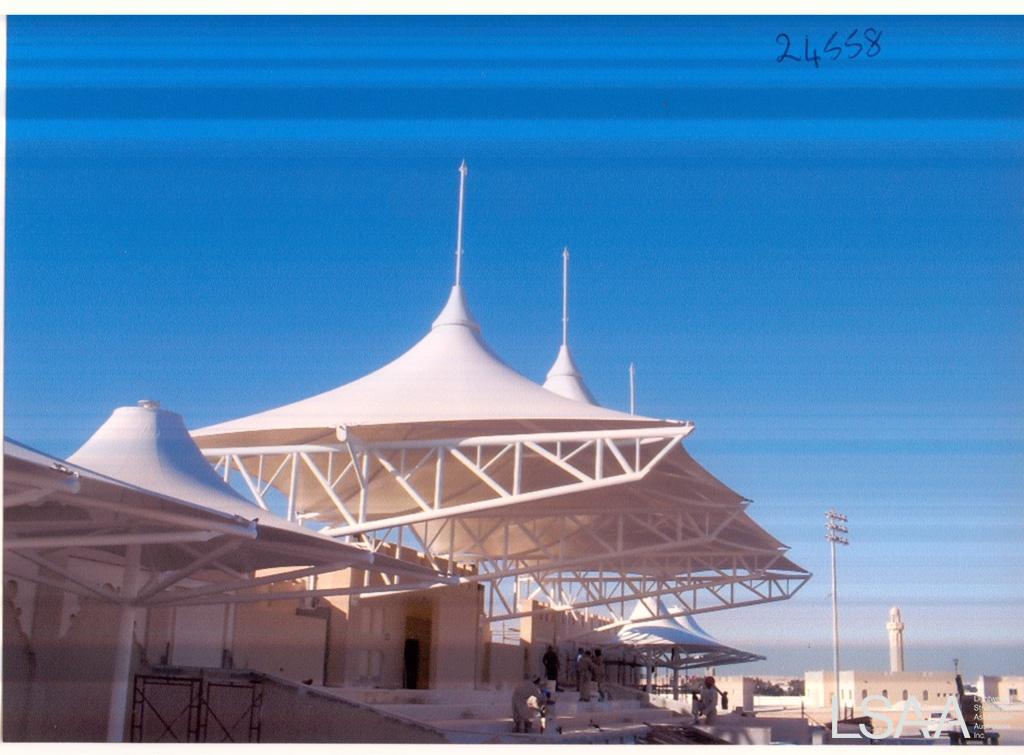

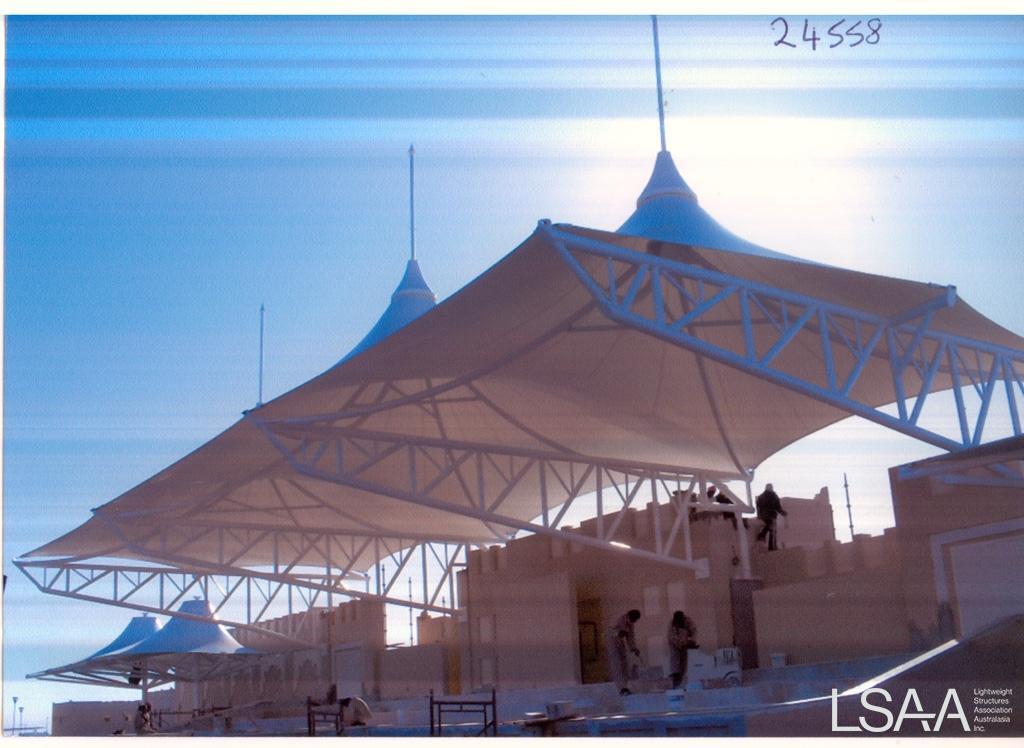

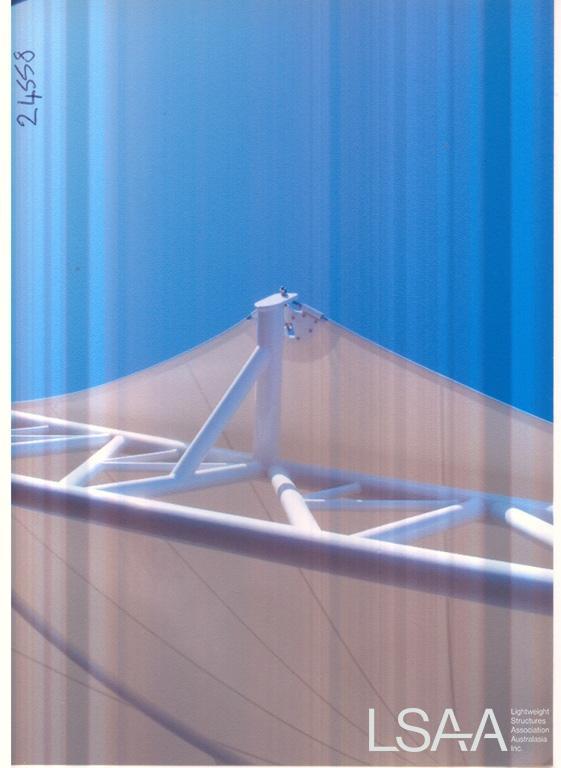

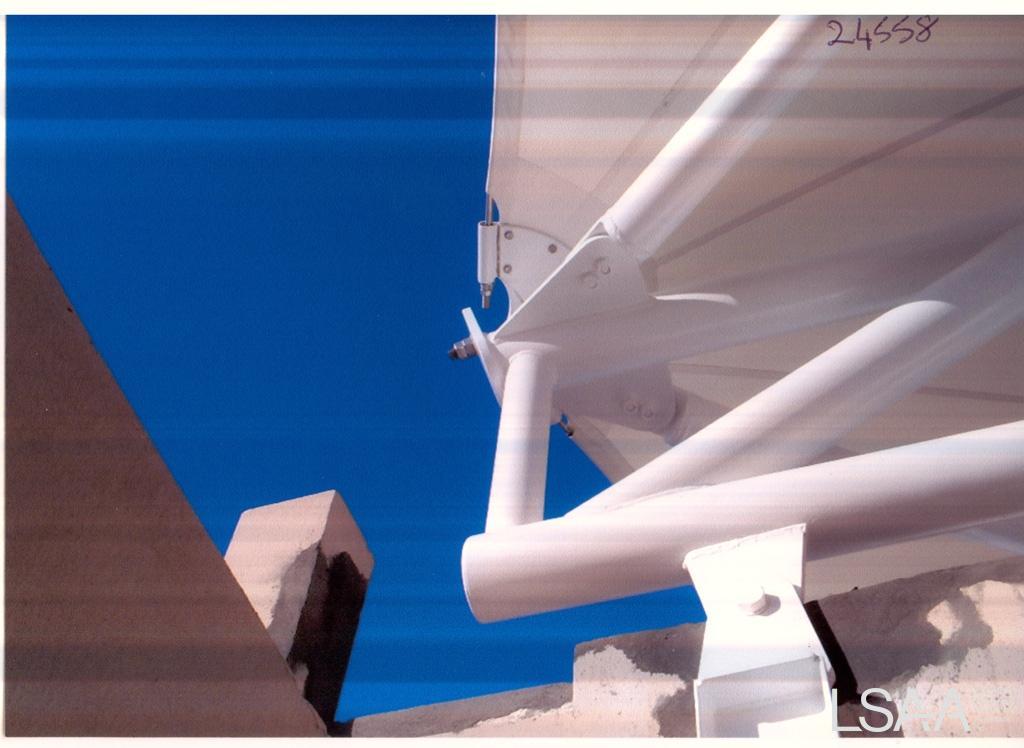

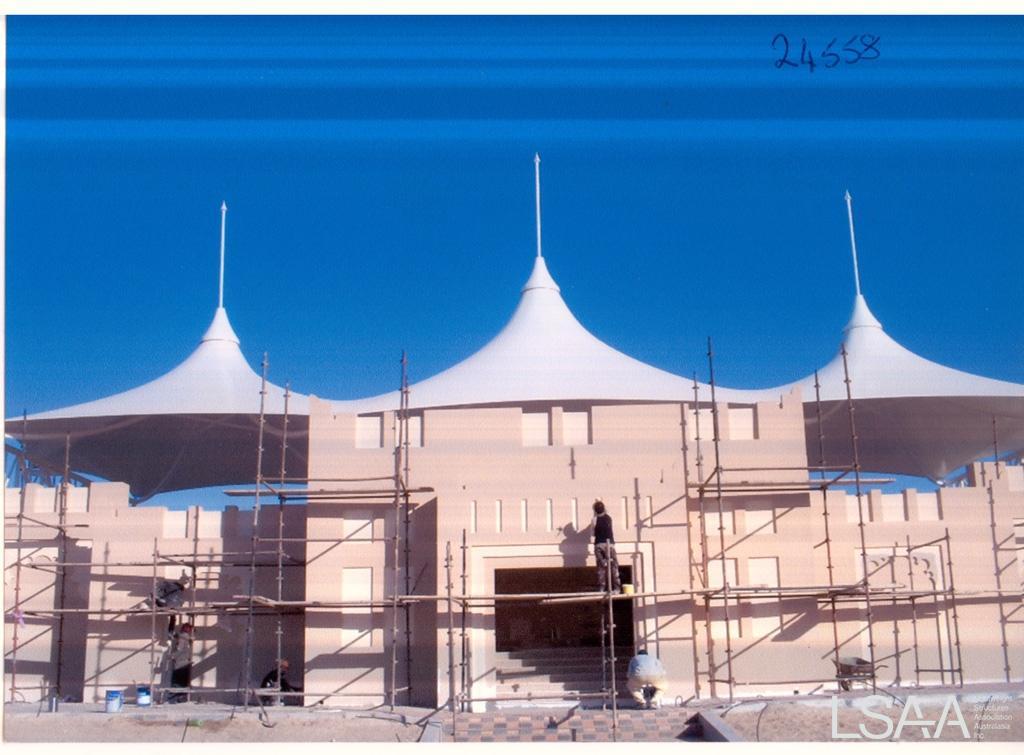

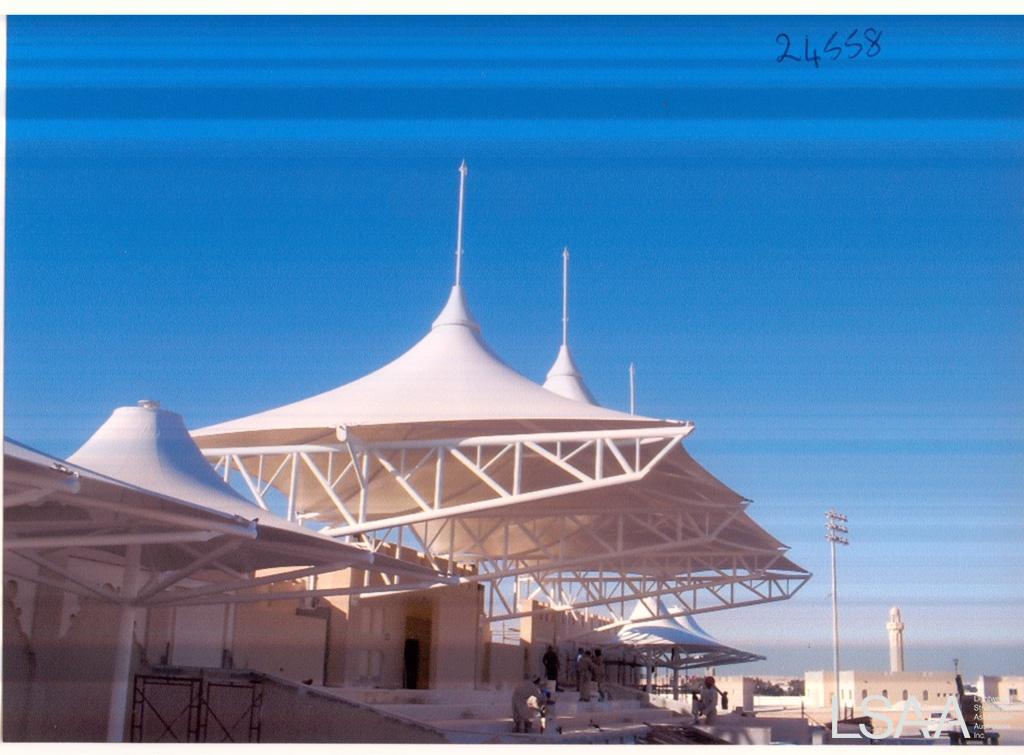

Entrant: Light Weight Structures Advisory Service - Engineering Fabrication Installation

Location: Isa Royal Military College - Kingdom of Bahrain

Client: Alasco Group & Al Alaa Shade Company

Struct. Eng.: Trevor Scott & Jeremy Hunter

Specialist: LTWSAS

Builder & Fabricator: Al Alaa Shade Company

This project was entered in the LSAA 2009 Design Awards (Cat 2, Medium Fabric Structures #24558)

No further details have been entered at this stage

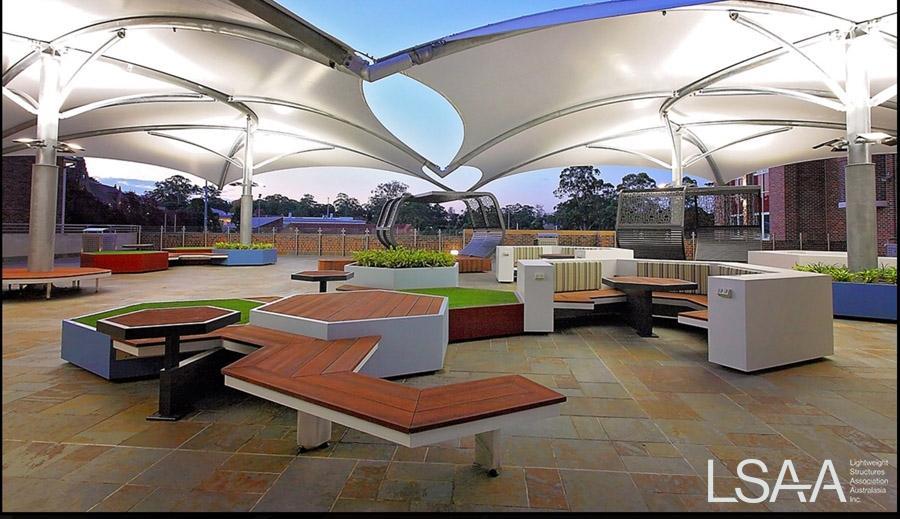

APPLICATION OF PROJECT:

The project was to design and install a unique waterproof shade structure to a Year 11/12 study area at an elite private Grammar School in Sydney.

The area under cover is 760sqm. The space to be shaded was clearly defined and located between the austere 19th century red brick buildings on a second floor flat tiled roof

PROJECT DESCRIPTION:

Beyond a school’s playing fields, exposed concrete surfaces often represented the extent of outdoor space in many schools built a century ago. Knox Grammar was no different.Today the definition of outdoor space is much more exciting and open to design possibilities. For schools with resources, outdoor spaces can be unique, comfortable, multifunctional and aesthetic.

DESIGN FABRICATION INSTALLATION BRIEF

The Kina building at Green School New Zealand was conceived as a groundbreaking educational facility, designed to embody sustainable and innovative principles. The client’s vision was for a building that would integrate biophilic design with neuroarchitecture, enhancing both cognitive function and emotional well-being. The challenge was to create a structure that not only supported Green School’s commitment to holistic education and environmental stewardship but also reflected a deep connection to nature.

In addressing the design brief, Fabric Structures focused on several key aspects. The project demanded the use of cutting-edge fabric materials that would contribute to both the aesthetic and functional goals of the building.

- Medium Structures - 2024DA -Tumbalong Green Amphitheatre

- Aquinas College Forum

- Laneways Canopy

- Shore School Pool Hall Skylight (DA 2022 Entry by MakMax)

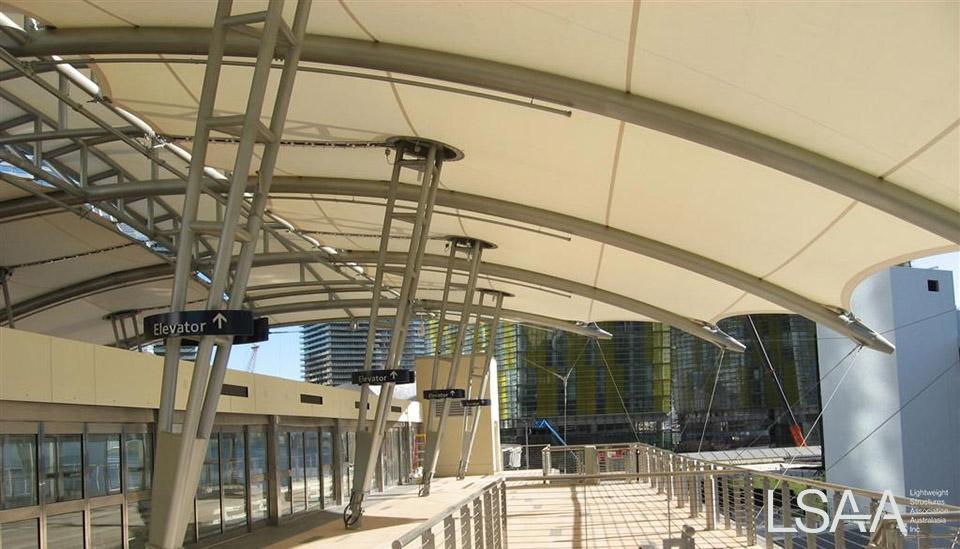

- CityCentre Automated People Mover

- Great Southern Oceans

- Dubai Outlet Mall Entrance Dome

- Southern Plaza Bar

- John Street Bridge - Whangarei, NZ

- Catholic College Bendigo

- La Piazza - Jakarta

- Medium Structures - 2024DA - MSU John Goodman Amphitheatre

Page 3 of 5